LDES, Thermal Energy Storage and Alumina Refineries

Thermal Energy Storage

Thermal energy storage (TES) systems store energy as heat and are a type of long-duration energy storage (LDES), meaning many of the technologies can store energy for over 10 hours. It’s ideal for storing energy during the day and releasing it at night or even 24x7, plugging the ‘peaks and troughs’ energy dilemma that the electricity grid can struggle with on sunny days or cold nights.

There are three types of TES; sensible heat, latent heat and thermochemical. During this case study, we’ll be using a TES technology example, MGA Thermal, which uses latent heat as the dominant storage mechanism. In plain terms, this storage material undergoes a phase change (i.e. melting).

MGA Thermal’s latent heat TES is unique as, due to the microstructure of the material, the MGA Blocks store energy through a phase change while remaining outwardly solid. The method reduces containment risks and overall makes the system more economical, having a higher energy density compared to other forms of TES, and a smaller physical footprint than sensible heat LDES technologies which reduces the cost of the balance of plant.

Why TES?

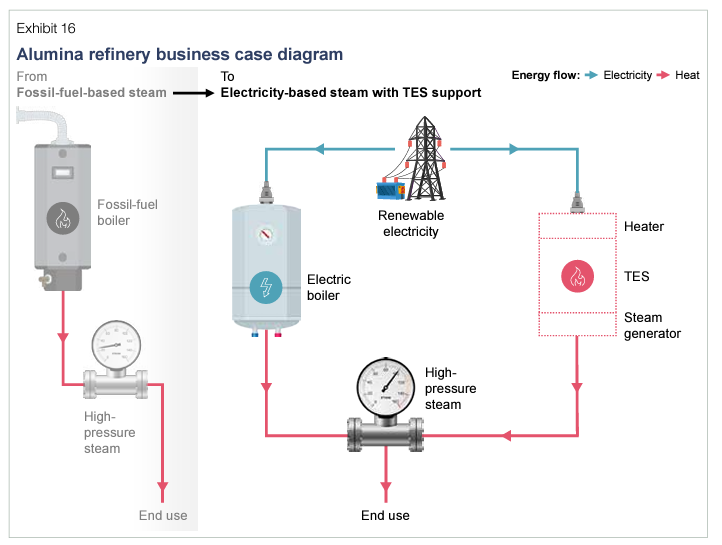

50% of the world's final energy consumption is used for heating (IEA, 2019). Historically, industrial processes have been consuming the heat provided by burning gas, coal, or oil, often to create steam in boilers. TES can provide decarbonised heat through electrification and storage, thereby replacing the burning of fossil fuels yet allowing industry to continue to operate without disruption.

Thermal energy storage can also provide both heat and electricity supply from stored renewable energy. This is called cogeneration and creates flexibility for industry to use heat energy for their manufacturing processes, and electricity for their business operations.

LDES typically stores renewable energy at times of excess supply. In addition, our example TES from MGA Thermal, decouples the charge and discharge in its design, that is it can charge and discharge simultaneously. As an example, this means the system could charge for 8 hours a day whilst discharging 24/7, thus powering industries that need to operate around the clock.

The LDES Council report ‘Driving to Net Zero Industry Through Long Duration Energy Storage’ found that in many applications, LDES can already electrify low-to-medium temperature processes at a more economical cost than alternatives. Read more about LDES as applied to industrial decarbonisation here.

Industrial heat

Industry has many considerations when looking to replace typical gas or coal-fired steam systems. Successfully decarbonising will require new scaling technologies that firm renewables and service a broad range of temperatures. Most processes currently use fossil fuels, and decarbonisation will require clean steam or process heat in temperatures ranging from less than 150°C to over 1000°C. The LDES Council suggests that existing LDES technologies can already address 65% of industrial emissions and provide a clear pathway to effective decarbonisation.

TES in an Alumina Refinery

What does an Alumina Refinery do?

Alumina or aluminium oxide, is a material manufactured partway through the aluminium refinement process. Mined bauxite ore is refined to alumina, which is then processed to produce aluminium.

The refining process used by alumina refineries (Bayer) involves digestion, clarification; precipitation and calcination. During this process, a large amount of process heat in the form of high-pressure steam is required at the digestion step and very high-temperature process heat is required at the calcination step.

The LDES Council report ‘Net-zero Heat’ uses a business case study with the below specifications.

Technical specifications

Baseload operation (>99% uptime), with daily TES charging cycles

Steam at ~104 barg and 325C (260GWh annual equivalent)

380MW electric boiler with 6.6 GWh TES replacing 380MW gas boiler

Upgrade 300km transmission line built to support additional 980MW grid capacity

~600,000tCO2 emissions saved annually

In this example from the LDES Council, a 6.6GWh Thermal Energy Storage System and a 380MW electric boiler replace a 380MW gas boiler, to provide heat for the digestion step.

MGA Thermal TES is ideally positioned to deliver the process steam in the alumina refinery. The MGA solution combines the electric boiler and storage functions into a single system. It is considered a highly flexible operation with daily charging cycles and the ability for co-generation with 24/7 discharge.

Key factors that contribute to ultimate costs and profitability are fossil fuel cost vs renewable electricity cost and CO2 price (or carbon tax). The LDES Council report found that the return on investment is even stronger when the business has access to behind-the-meter solar electricity.

Benefits of TES in Alumina Refineries

Flexibility: TES allows flexible charging. TES systems can charge at times of low grid demand and store the energy to use at any time of the day. This flexibility helps to level out the load on the grid and may unlock additional grid service value streams. Some grid networks may begin reducing fees for electricity transmission (grid demand fees) and offer remuneration for flexibility – accepting TES as a grid asset because it doesn’t add to the load during times of stress.

Co-generation: Combined heat and power TES technologies that are capable of making very high-temperature steam like MGA Thermal can also drive steam turbines prior to providing the heat energy for alumina digestion. Generating both heat and power with the one storage technology improves flexibility whilst helping to reduce cost, complexity and resources used.

Variable pricing: Many grids around the world have variable spot prices. This unlocks the refinery's ability to capitalise on variable electricity pricing - buying while the price is low or even negative. It also avoids any increases in the price of fossil fuels as climate change increases global tensions.

Reducing CO2: reducing emissions and decarbonising the refinery will decrease carbon taxes, depending on the country and region’s policies. Carbon taxes are set to become increasingly common as emission reduction targets grow closer- read LDES, Industrial Heat and Decarbonisation Policy. Most importantly, reducing CO2 emissions enables refineries to meet Net Zero obligations and help curb the effects of climate change.

Our technology, MGA Thermal, is ideal to decarbonise Alumina refineries, ready to address industrial heat, steam or steam + power applications between 150°C and 600°C. If you’d like a techno-economic assessment of how TES could work in your industry, submit your project details here.